Marble is more than just a beautiful stone. It tells stories of nature’s mystery and craftsmanship’s care. If you’ve ever wondered how marble manufacturers create those smooth, strong, and perfect slabs, this blog will take you through that fascinating journey. Whether you are looking for a stone supplier or curious about how the best marble, like Kishangarh marble, is prepared, this step-by-step guide will help you understand the process clearly and simply.

How Stone Suppliers Near You Select Raw Marble

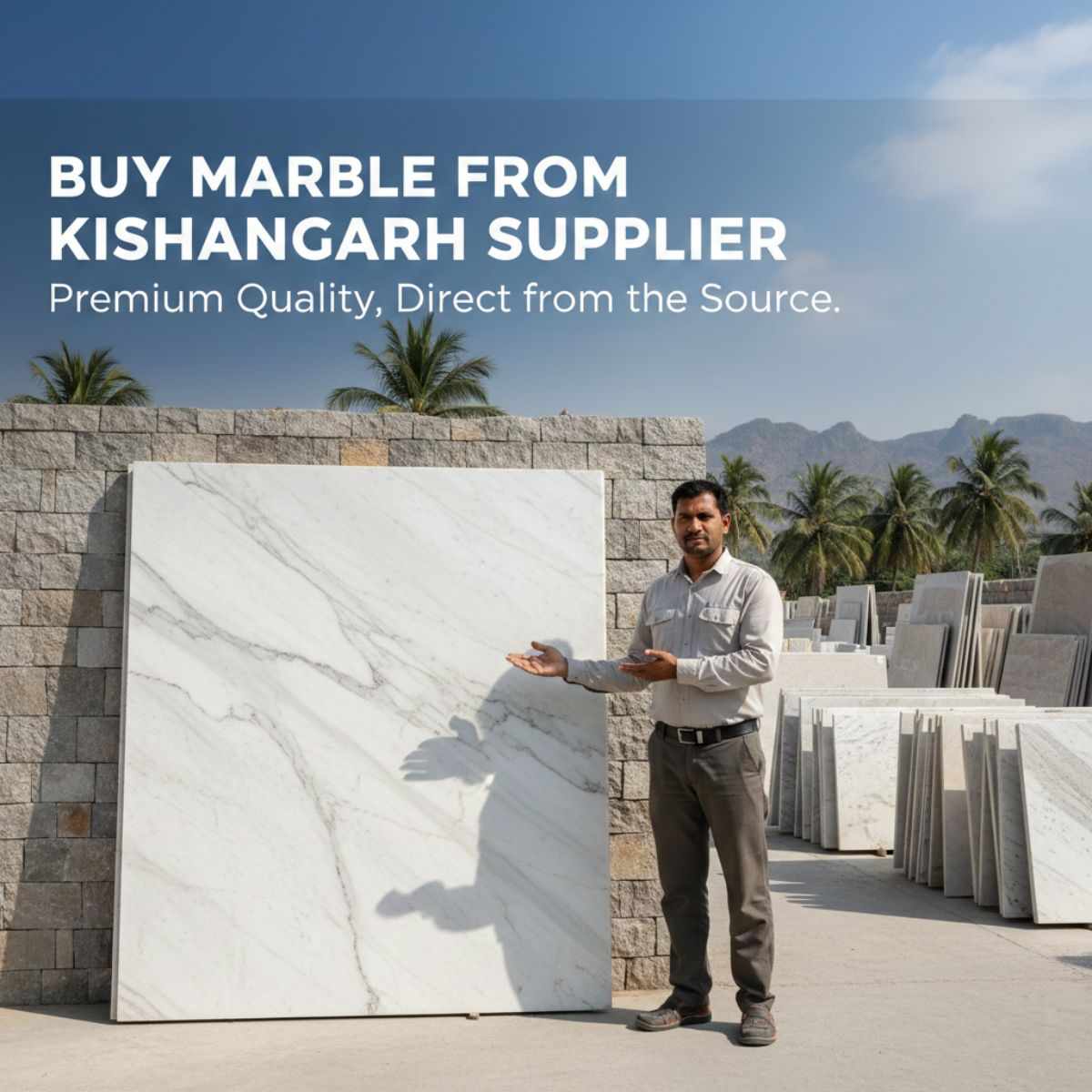

The journey starts deep inside marble quarries. Stone suppliers near you, especially those in marble-rich areas like Kishangarh, begin by selecting the best raw blocks of marble. This is a critical stage because the quality of marble depends largely on the initial stone. Suppliers like Imperial Stones, a trusted Kishangarh marble supplier, hand-pick large-sized blocks that show no signs of cracks or defects. They look for natural colors and patterns that make each marble unique.

Once the blocks are chosen, they are carefully cut out from the quarry using heavy machinery. This raw marble then travels to the manufacturing unit for further processing. For a Marble Supplier in Kishangarh, having a steady supply of high-quality raw marble is the key to producing premium slabs.

Cutting and Dressing: The First Step to Shaping Marble

After the raw marble reaches the factory, manufacturers begin shaping it. First, they use special block dressing machines to trim off uneven edges and unwanted parts. This ensures that each block has a smooth outline.

Next, the blocks undergo cutting with advanced tools such as diamond wire saws or CNC machines, which allow precise and clean cuts. This careful cutting helps maintain the strength of the marble while creating slabs of consistent thickness.

In this phase, manufacturers also remove any weak or flawed areas that might spoil the final product. The result is a set of uniform marble slabs ready for polishing and finishing.

Polishing and Strengthening for High Quality Stone

One of the secrets to high-quality marble is in the polishing process. This step brings out the stone’s natural beauty, making its surface gleam while protecting it from damage. Manufacturers like Imperial Stones, a leading Kishangarh marble supplier, often apply a special resin or epoxy coating. This resin fills tiny cracks and strengthens the edges, making the marble more durable and less likely to chip.

Polishing machines with multiple heads grind and smooth the marble slab surfaces evenly. The manufacturers adjust the pressure and speed depending on each stone’s natural texture, ensuring a flawless finish without damaging the marble.

This polishing process is not just about looks; it also improves the stone’s resistance to wear, making it suitable for floors, countertops, and walls where durability matters.

Quality Checks by Marble Manufacturers and Stone Suppliers

Stone suppliers understand that even a beautiful marble slab is not good if it is weak or uneven. So, quality control is a major part of the manufacturing process. Each slab undergoes thorough inspection to check color consistency, surface smoothness, and structural strength.

This checking often involves stacking and weighing slabs to ensure uniform thickness and strength. Any slab that shows signs of flaws is removed from the lot.

Manufacturers use high-tech equipment as well as manual inspection to guarantee that customers receive only the best stone. For buyers, working with a reliable Marble Supplier in Kishangarh like Imperial Stones means getting marble that will last and look stunning for years.

Packaging and Delivery by Stone Suppliers Near You

After passing quality control, marble slabs are carefully packed to avoid damage during transport. Manufacturers wrap them in fiber sheets or cushioned materials for extra protection.

Finally, stone suppliers arrange for delivery to clients. Whether for a small home renovation or a large construction project, the marble slabs are safely delivered, ready for installation.

If you are searching for a stone supplier or a Kishangarh marble supplier for your next project, consider those with a good reputation for quality and service, like Imperial Stones.

In conclusion, making high-quality marble stone is a detailed and careful process. From selecting the right raw blocks to polishing and quality inspection, each step matters. Knowing how marble manufacturers work helps buyers appreciate the value behind every polished slab, whether from a local stone supplier or a specialist like a Kishangarh marble supplier. Trust in quality, craftsmanship, and experience for the best marble stone.

Write a comment ...